August 31, 2025

Corrosion-Resistant Materials for Saltwater Tank Longevity

Understanding the Challenges of Saltwater Environments

Saltwater environments are notoriously harsh on materials due to the corrosive nature of seawater. The high salinity, combined with the presence of microorganisms and fluctuating temperatures, accelerates the degradation of many common materials. For saltwater tanks, this poses a significant challenge, as the integrity of the tank directly impacts the health of the aquatic life it houses. Understanding the specific challenges posed by saltwater is the first step in selecting the right materials for long-lasting tank construction.

Key Properties of Corrosion-Resistant Materials

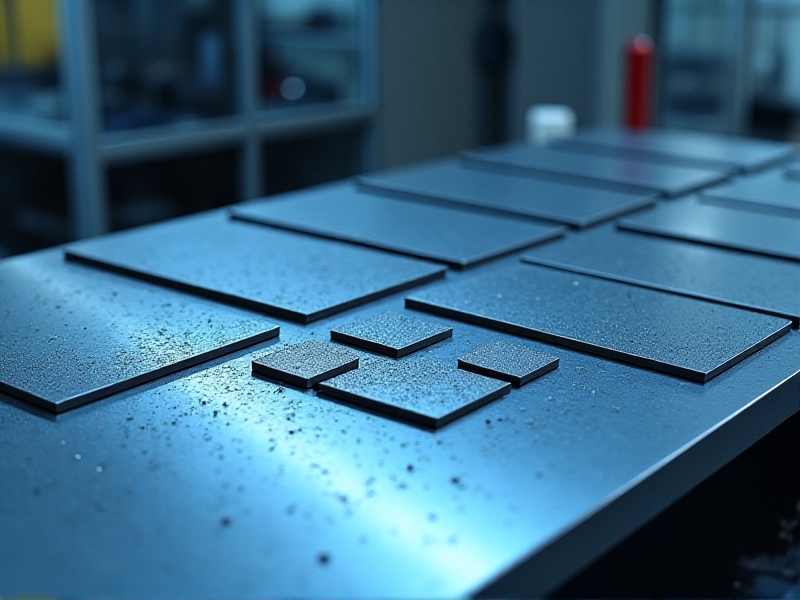

When selecting materials for saltwater tanks, several key properties must be considered. These include resistance to corrosion, durability, and non-toxicity. Materials such as stainless steel, titanium, and certain plastics are often favored for their ability to withstand the harsh conditions of saltwater. Additionally, the material's ability to resist biofouling—the accumulation of microorganisms, plants, and algae—is crucial for maintaining a clean and healthy tank environment.

Stainless Steel: A Popular Choice for Saltwater Tanks

Stainless steel is one of the most commonly used materials in saltwater tank construction due to its excellent corrosion resistance and strength. However, not all stainless steel grades are created equal. Grades such as 316L, which contain molybdenum, offer superior resistance to saltwater corrosion compared to other grades. Despite its advantages, stainless steel can still be susceptible to pitting and crevice corrosion if not properly maintained, making regular inspection and cleaning essential.

Titanium: The Ultimate Corrosion-Resistant Material

Titanium is often considered the gold standard for corrosion-resistant materials in saltwater environments. Its exceptional resistance to corrosion, even in highly saline conditions, makes it an ideal choice for critical components in saltwater tanks. Titanium is also lightweight and strong, adding to its appeal. However, the high cost of titanium can be a limiting factor, making it more suitable for specialized applications rather than entire tank constructions.

Plastics and Composites: Affordable and Durable Alternatives

Plastics and composite materials offer an affordable and durable alternative to metals in saltwater tank construction. Materials such as PVC, acrylic, and fiberglass are widely used due to their resistance to corrosion and ease of fabrication. These materials are also non-toxic, making them safe for aquatic life. However, the choice of plastic or composite must be carefully considered, as some types may degrade over time when exposed to UV light or certain chemicals in the water.

Protective Coatings and Treatments

In addition to selecting corrosion-resistant materials, protective coatings and treatments can further enhance the longevity of saltwater tanks. Epoxy coatings, for example, provide an additional layer of protection against corrosion and biofouling. Regular maintenance, such as cleaning and applying anti-corrosion treatments, can also extend the life of the tank. It's important to choose coatings that are safe for aquatic life and do not leach harmful chemicals into the water.

Case Studies: Successful Applications of Corrosion-Resistant Materials

Several real-world examples demonstrate the successful use of corrosion-resistant materials in saltwater tanks. For instance, public aquariums often use a combination of stainless steel, titanium, and acrylic to construct large, durable tanks that can withstand the rigors of saltwater environments. These case studies provide valuable insights into the practical application of these materials and the maintenance practices that contribute to their longevity.

Future Trends in Corrosion-Resistant Materials

As technology advances, new materials and treatments are being developed to further improve the corrosion resistance of saltwater tanks. Innovations such as nanotechnology coatings and self-healing materials hold promise for even greater durability and reduced maintenance. Additionally, the growing emphasis on sustainability is driving the development of eco-friendly materials that are both corrosion-resistant and environmentally benign.

Maintenance Tips for Prolonging Tank Longevity

Proper maintenance is key to ensuring the longevity of saltwater tanks, regardless of the materials used. Regular cleaning, monitoring water quality, and promptly addressing any signs of corrosion or wear can prevent small issues from becoming major problems. Establishing a routine maintenance schedule and using the right tools and products will help keep the tank in optimal condition for years to come.