August 31, 2025

Emergency Drainage Systems for Float Tank Malfunction Scenarios

Understanding Float Tanks and Their Importance

Float tanks, also known as sensory deprivation tanks, have gained popularity for their therapeutic benefits, including stress reduction, improved sleep, and enhanced creativity. These tanks are filled with a saline solution that allows users to float effortlessly, creating a sense of weightlessness. However, like any other equipment, float tanks can malfunction, leading to potential hazards such as water leakage or electrical issues. Understanding the importance of emergency drainage systems in these scenarios is crucial for ensuring user safety and preventing damage to the tank and surrounding environment.

Common Float Tank Malfunctions and Their Implications

Float tanks can experience a variety of malfunctions, each with its own set of implications. One common issue is water leakage, which can occur due to cracks in the tank or faulty seals. This not only poses a safety risk but can also lead to water damage in the surrounding area. Electrical malfunctions, such as short circuits or overheating, are another concern, especially since float tanks rely on electrical components for heating and filtration. In such cases, an emergency drainage system can help mitigate the risks by quickly removing water and reducing the potential for electrical hazards.

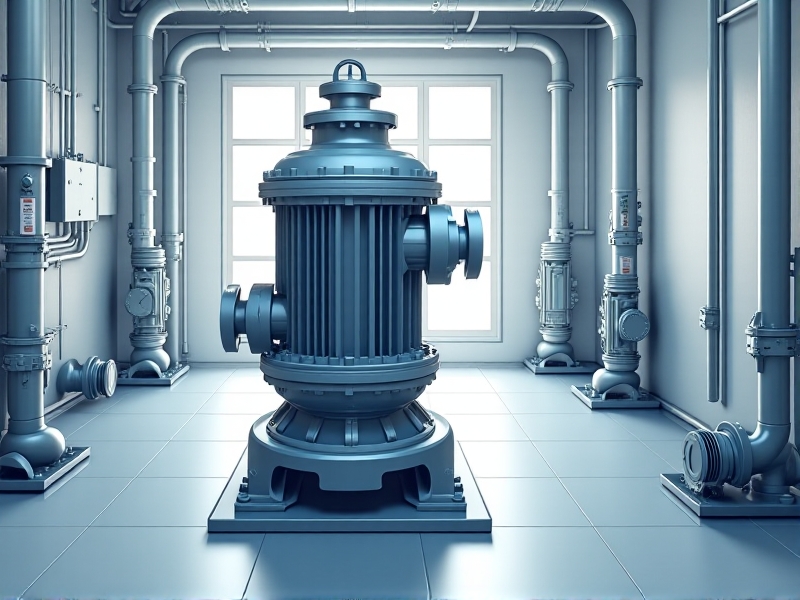

Designing an Effective Emergency Drainage System

An effective emergency drainage system for a float tank should be designed with several key factors in mind. First, it should be capable of quickly removing large volumes of water to prevent flooding. This can be achieved through the use of high-capacity pumps and wide-diameter drainage pipes. Second, the system should be easy to activate, even in an emergency situation. This could involve the use of manual overrides or automated sensors that detect water levels and activate the drainage system when necessary. Finally, the system should be designed to minimize the risk of electrical hazards, with all components properly insulated and grounded.

Maintenance and Testing of Emergency Drainage Systems

Regular maintenance and testing are essential to ensure that an emergency drainage system remains functional when needed. This includes routine inspections of pumps, pipes, and sensors to identify and address any potential issues before they become serious problems. Testing the system periodically, such as by simulating a water leakage scenario, can help verify that it operates as expected. Additionally, keeping a log of maintenance activities and test results can provide valuable documentation for troubleshooting and ensuring compliance with safety standards.

Legal and Safety Standards for Float Tank Drainage Systems

Float tanks are subject to various legal and safety standards, which often include requirements for emergency drainage systems. These standards may specify the minimum capacity of the drainage system, the types of materials that can be used, and the frequency of maintenance and testing. Compliance with these standards is not only a legal obligation but also a critical aspect of ensuring user safety. Operators of float tanks should familiarize themselves with the relevant regulations in their area and take steps to ensure that their emergency drainage systems meet or exceed these requirements.

Case Studies: Real-Life Float Tank Malfunction Scenarios

Examining real-life scenarios where float tank malfunctions occurred can provide valuable insights into the importance of emergency drainage systems. For example, a case study might involve a float tank that experienced a significant water leak due to a cracked seal. In this scenario, the emergency drainage system was able to quickly remove the water, preventing flooding and minimizing damage to the surrounding area. Another case study could involve an electrical malfunction that caused the water in the tank to overheat. Here, the drainage system played a crucial role in reducing the risk of injury by quickly removing the hot water and allowing for safe access to the tank.

Future Innovations in Float Tank Safety and Drainage

As technology continues to advance, new innovations in float tank safety and drainage are likely to emerge. For example, smart sensors could be integrated into the tank to monitor water levels, temperature, and other critical parameters in real-time. These sensors could automatically activate the emergency drainage system when a potential issue is detected, providing an additional layer of safety. Additionally, advancements in materials science could lead to the development of more durable and corrosion-resistant components for drainage systems, further enhancing their reliability and longevity.